The aluminum substrate is similar to the single-panel process of the FR-4 epoxy fr4 board, mainly because there is no electroplating process.

FR-4 epoxy board is a code name of fire-resistant material. It means a material specification that the resin material must be self-extinguishing after being burned. It is not a material name, but a material grade. At present, there are many types of FR-4 epoxy grade materials used in general circuit boards, but most of them are made of so-called four-function (Tera-Function) epoxy grease plus filler (Filler) and glass fiber. which was made by the composite material .

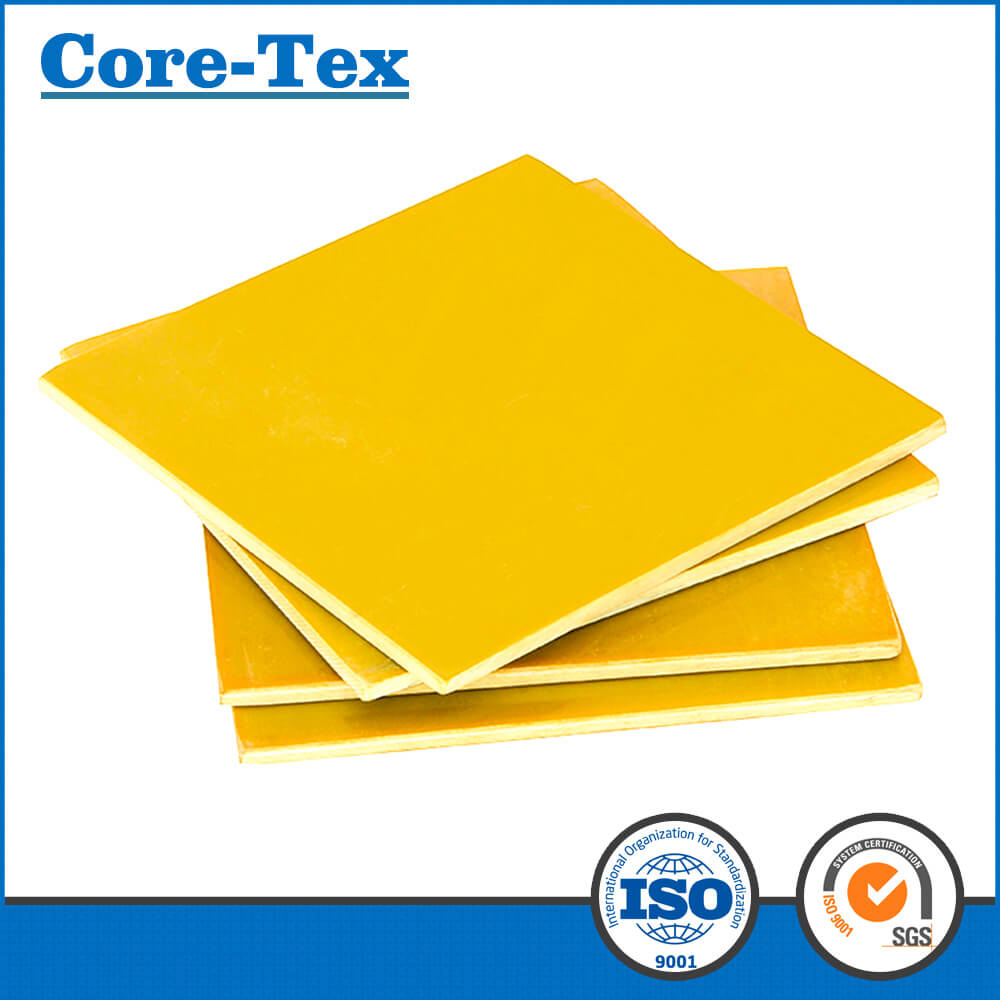

FR-4 epoxy glass cloth laminates sheet, according to the use of the industry, it is generally called:

FR-4 Epoxy Glass Cloth, Insulation Board, Epoxy Board, Epoxy Board, Brominated Epoxy Board, FR-4, Fiber glass Board, Fiberglass Board, FR-4 Reinforced Sheet, FPC Reinforced Sheet, Flexible Circuit board reinforcement board, FR-4 epoxy resin board, flame retardant insulation board, FR-4 laminated board, epoxy board, FR-4 light board, FR-4 glass fiber board, epoxy glass cloth board, epoxy Glass cloth laminate, circuit board drilling pad

Main technical features and applications:

performance stable electrical insulation , good flatness, smooth surface, no pits, standards thickness tolerance , suitable for high performance electronic insulation requirements, such as FPC reinforcement board, PCB drilling pad, glass fiber meson, potentiometer carbon Film printing fiberglass board, precision planetary gear (wafer grinding), precision test board, electrical (electrical) equipment insulation struts, insulation pads, transformer insulation board, motor insulation parts, grinding gears, electronic switch insulation boards, etc.

The aluminum substrate is a metal-based copper clad laminate with good heat dissipation function. Generally, the single panel is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer.

when it is designed as a double panel,it also used for high-end place ,the structure is circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. A very small number of applications are multi-layer boards, which can be made of ordinary multi-layer boards combined with an insulating layer and an aluminum base. The LED aluminum substrate is the PCB, which is also the meaning of the printed circuit board. The material of the circuit board is aluminum alloy. In the past, the material of our general circuit board was glass fiber, but because the LED heat is large, the circuit board for LED lamps is generally the aluminum substrate which can conduct heat quickly, and the circuit board for other equipment or electrical appliances is also a fiberglass board.