The fiberglass board and the cold-punching board are used for the soft-packing base layer, and the outer fabric is covered with fabric, leather, etc., it is made into a beautiful wall surface and ceiling decoration. The application is very wide, and it can have sound absorption, sound insulation and heat insulation,Environmental protection, flame retardant and other characteristics.

There is also a special ceiling glass fiber slab, which is not made of fabric and leather. It is decorated with white or black decorative felt. It is used as a ceiling for noise reduction and fire protection. It is used in bank supermarkets. Furniture factory schools and other places with high fire protection requirements.

The construction technology of the fiberglass board, the construction process of the glass fiberboard ceiling is the same as that of the mineral wool board. Firstly, determine the height of the ceiling, find the level, and then cut the whole tooth screw according to the height, fix the screw to the top with the expansion, and connect the lower end with light. Steel main keel, then use the mobile hanging piece to hang the painted keel or aluminum keel on the light steel keel. The last step is to put the fiber reinforced plastic board on the painted keel or aluminum keel. Note that it must be kept on the upper glass fiber board. Clean your hands or put on white gloves and stain the boards.

Then, what kind of material is the fiberglass board.

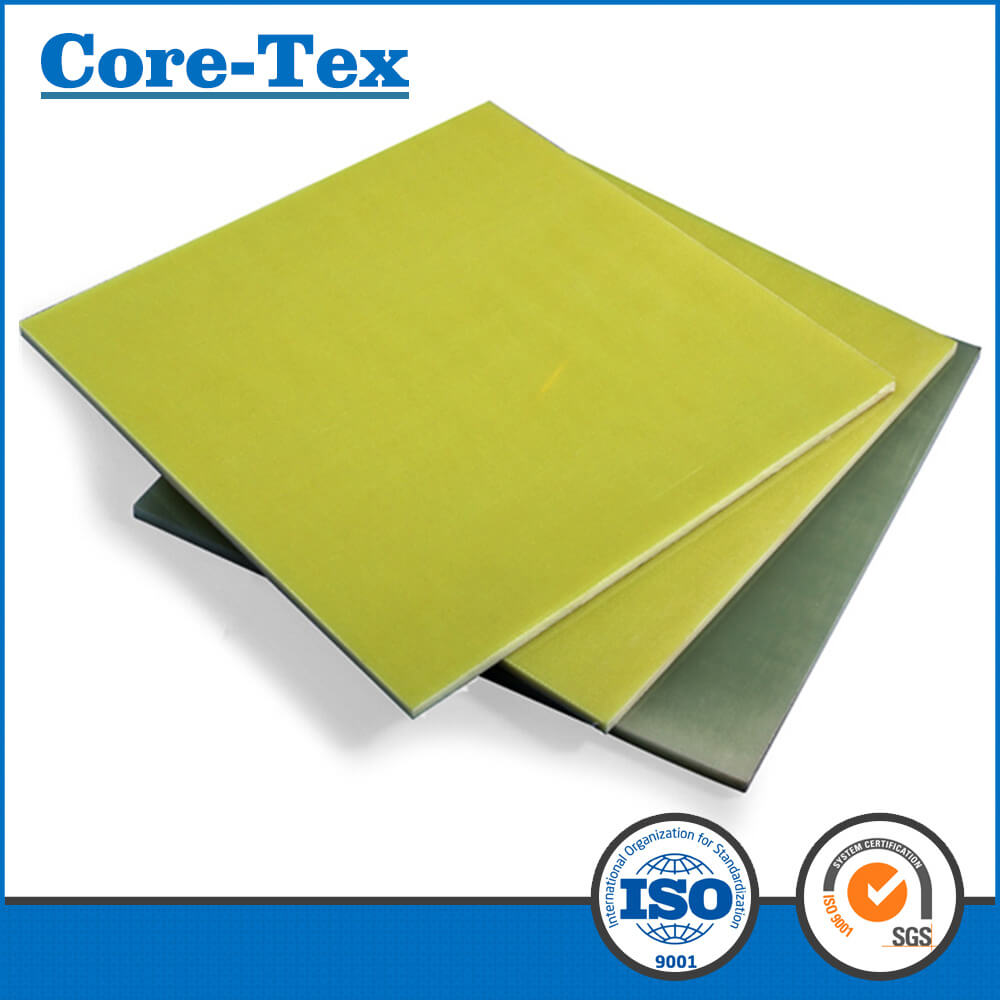

First, the fiberglass board is aliased to fiberglass insulation board and fiberglass board (FR-4). Glass fiber composite board, synthesized from glass fiber material and high heat resistance composite material, does not contain harmful asbestos components, it has high mechanical and dielectric properties, good heat resistance and moisture resistance, and it has good Processability for plastic molds, injection molds, machine building, forming machines, drilling machines, injection molding machines, motors, PCB.ICT fixtures, countertop polishing pads.

Injection mold molding usually requires: high temperature materials and low temperature molds. Insulation method must be used in the same machine condition to keep the injection molding machine at a low temperature and not to make the temperature of the injection molding machine too high. This requirement can be met by installing an insulating insulation panel between the injection molding and the injection molding machine. Shorten production cycle, increase productivity, reduce energy consumption, improve finished product quality, continuous production process ensures product quality is stable, prevents machine overheating, no electrical failure, no leakage of hydraulic system.