3242 Epoxy Glass Cloth Laminate Sheet

| Specification Overview | |

| Name | 3242 Epoxy Glass Cloth Laminate Sheet |

| Base Material | Epoxy resin + Fiber glass |

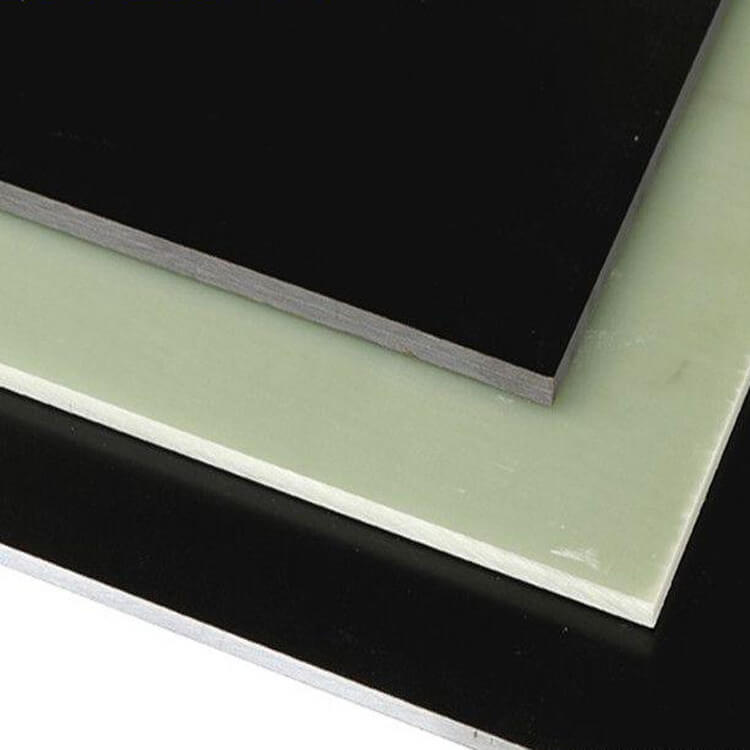

| Color | Green\yellow\red\black\white,etc (Color can be customized according to customer requirements) |

| Thickness | 0.1mm – 300mm ( More than 300mm can be produced according to product requirements) |

| Dimensions | Regular size are 1020x1220mm,1020x2040mm,1220x2440mm; Special size, we can produce and cut according to customer’s requirements. |

| Density | 1.97g/cm3 – 2.2 g/cm3 |

| OEM | Accepted |

Product Introduction

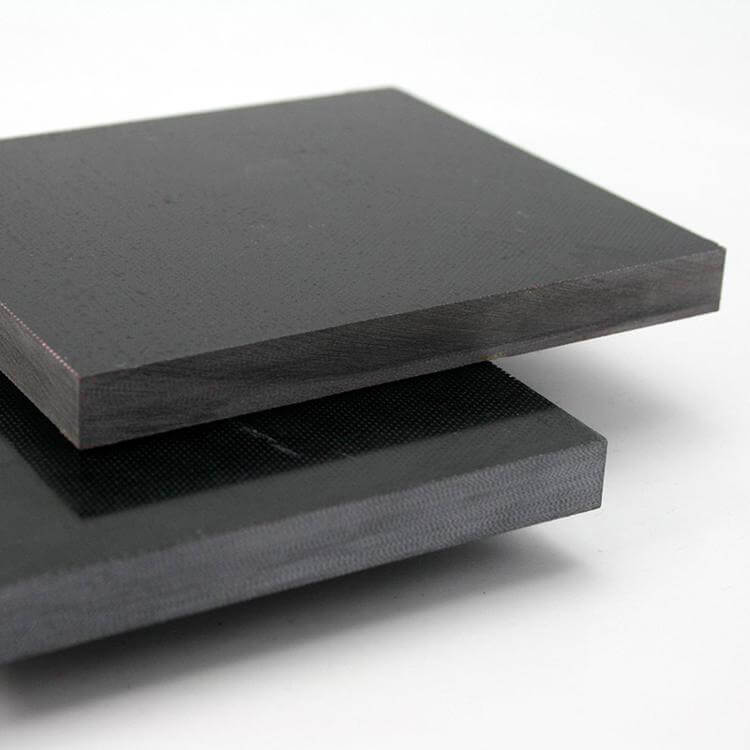

This laminated sheet is made of chemically treated electrical alkali-free glass fiber cloth as the base material and epoxy resin as the adhesive by hot pressing. It has high mechanical strength at high temperature and stable electrical performance under high humidity. It has good performance and belongs to F grade heat-resistant insulating material. It can be used for all kinds of electrical machinery, electrical appliances, electronics and other fields.

It is widely used in the isolation and support of inverters,motors, electronic appliances, aluminum batteries, new energy, electrical equipment, distribution boxes, fixture boards, mold plywoods, high and low voltage wiring boxes, packaging machines, combs, Mechanical molds, forming machines, drilling machines, table polishing pads, insulating frameworks, insulating coil frameworks, transformer frameworks, etc.

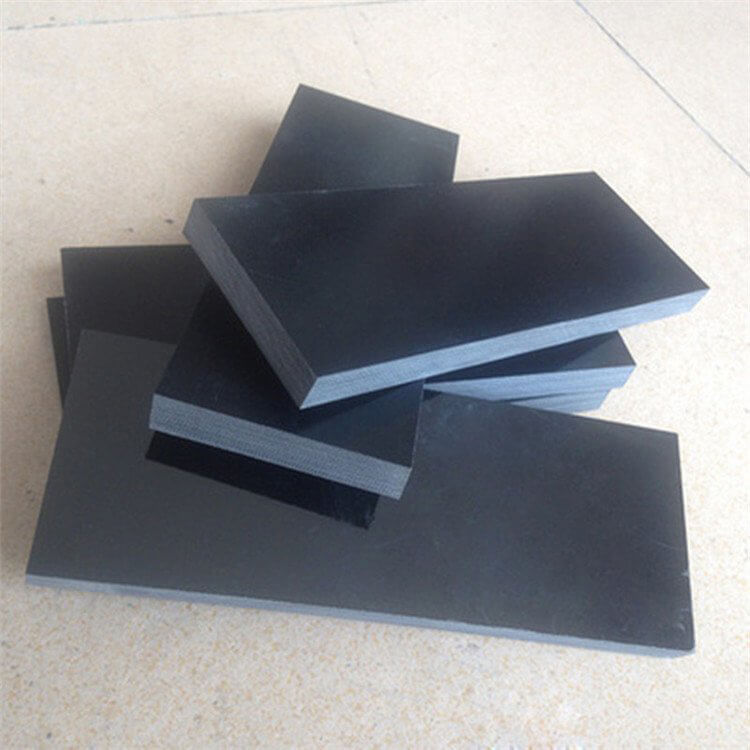

Product Photograph

Main Specifications

| Indicator Name | Unit | Indicator Value | |

| Density | g/ cm³ | 1 . 8 – 2 . 0 | |

| Water Absorption | % | ≤ 0 . 5 | |

| Vertical layer bending strength | Normality | MPa | ≥ 340 |

| 155 ± 2 ℃ | ≥ 170 | ||

| Parallel layer impact strength (simple beam method notch) | Longitudinal without gap | K J/ m² | ≥ 147 |

| Horizontal without gap | ≥ 98 | ||

| Compressive strength | Vertical layer | MPa | ≥ 300 |

| Parallel layer | ≥ 200 | ||

| Bond strength | N | ≥ 6800 | |

| Tensile Strength | Vertical | MPa | ≥ 280 |

| Horizontal | ≥ 200 | ||

| Rockwell hardness | HRM | ≥ 111 | |

| Vertical layer direction electric strength | 1mm | KV/ mm | ≥ 14 . 2 |

| 2mm | ≥ 11 . 8 | ||

| 3mm | ≥ 10 . 2 | ||

| Parallel layer direction breakdown voltage (90 ℃ ± 2 ℃ oil for 1 min) | KV | ≥ 35 | |

| Dielectric loss factor (50 Hz) | / | ≤ 0 . 04 | |

| Parallel layer to insulation resistance | Normality | Ω | ≥ 1 . 0 × 101 2 |

| After immersed in water for 24 h | ≥ 1 . 0 × 101 0 | ||

FAQ

Q1: Samples

We can send you free sample,but you need to pay for the shipping charge.

Q2: How about the quality of mass production ?

Our warehouse staff will keep another sample the same as you received.the production process will be under your requirement.please rest assured about the quality.

Q3: Delivery time

It depends on order quantity.Generally speaking, the delivery time will be within 7 to 15 days.

Q4: Package

We will use professional craft paper to package on plywood pallet.if you have special package requirements, we will pack as your need.

Q5: Payment

We accept T/T,L/C,Western Union,Paypal , etc.