Unlocking the Mysteries of FR4: The Backbone of Modern Electronics

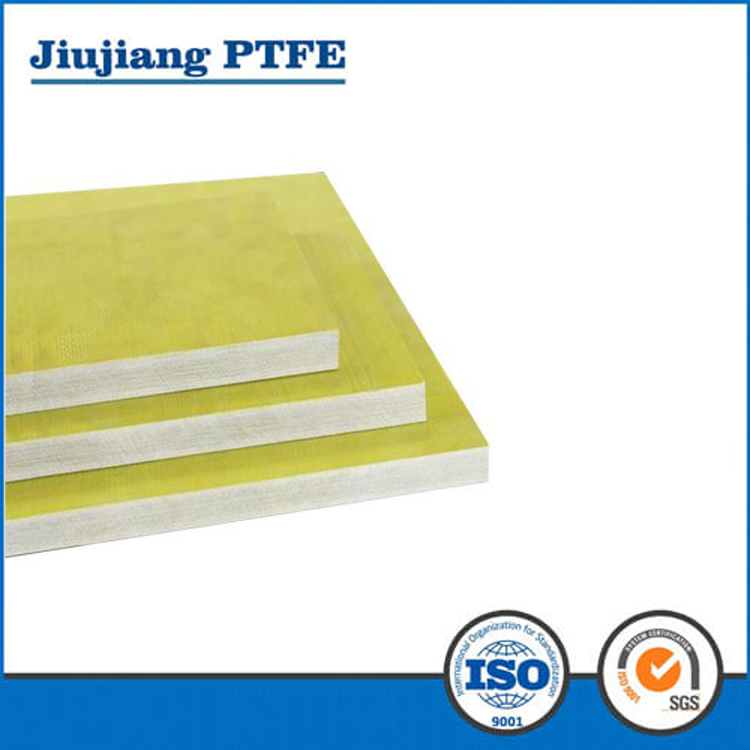

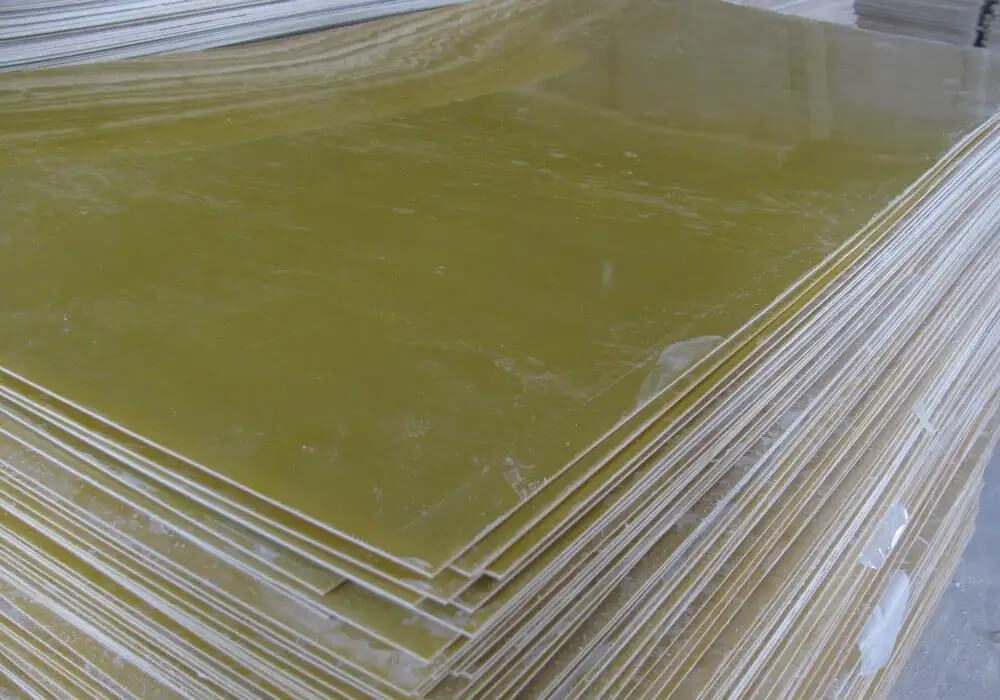

In the realm of electronics manufacturing, the choice of substrate material can significantly influence the performance, durability, and cost-effectiveness of the final product. Among the myriad options available, FR4 emerges as a frontrunner, revered for its exceptional mechanical and electrical [...]