In the realm of electronics manufacturing, the choice of substrate material can significantly influence the performance, durability, and cost-effectiveness of the final product. Among the myriad options available, FR4 emerges as a frontrunner, revered for its exceptional mechanical and electrical properties. But what exactly is FR4, and why does its density matter in the electronics industry? This article delves into the essence of FR4, exploring its characteristics, applications, and the pivotal role it plays in the development of electronic devices.

What is FR4?

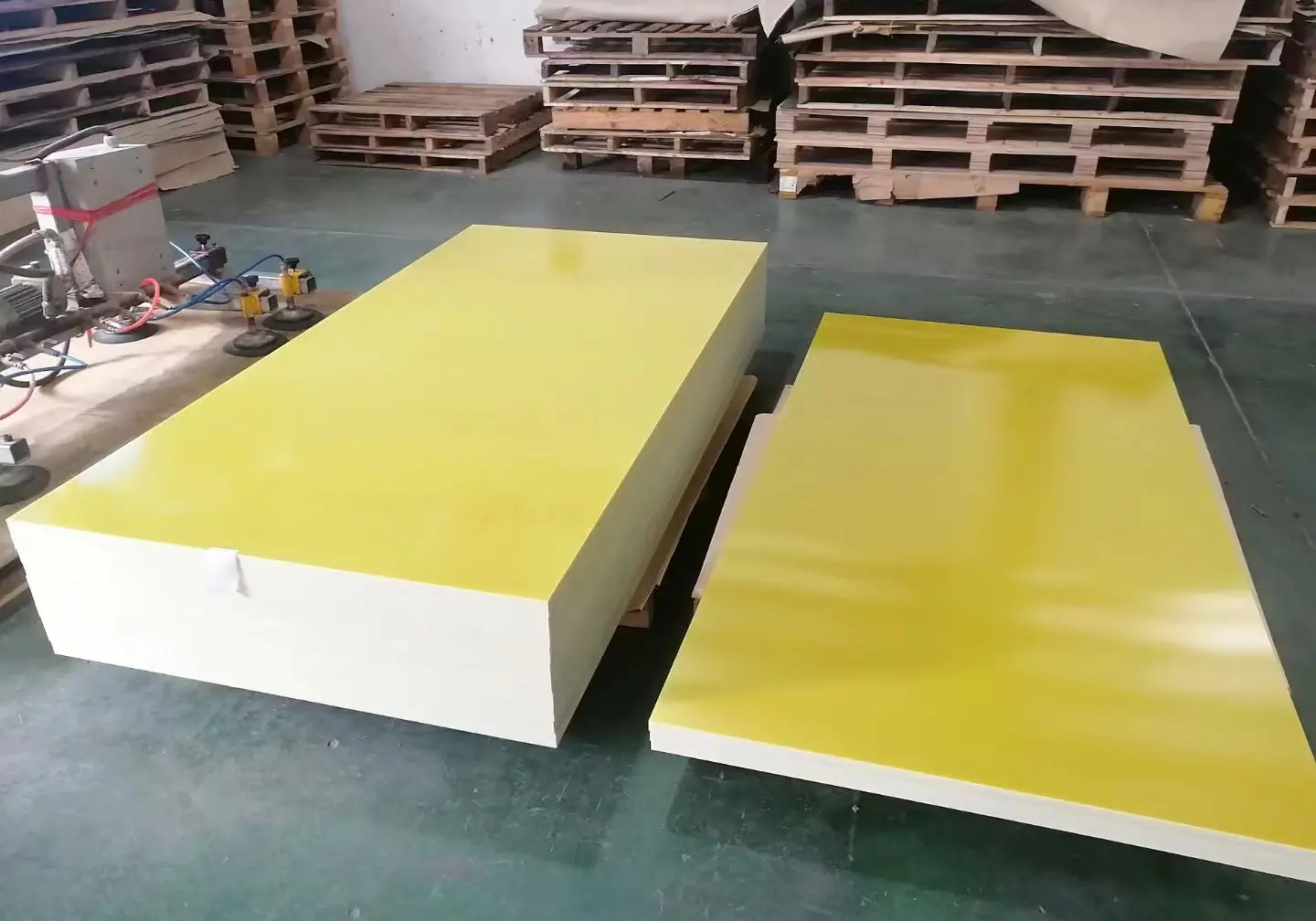

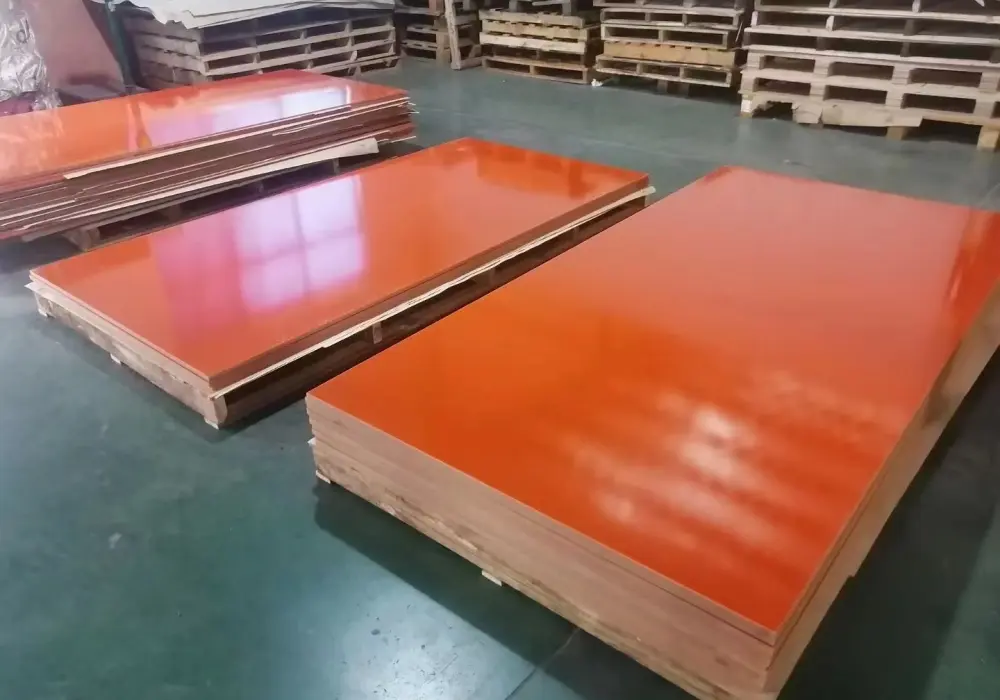

FR4 is a grade designation assigned to a composite material composed of woven fiberglass cloth with an epoxy resin binder. This combination endows FR4 with remarkable strength, resistance to moisture, and electrical insulating properties, making it an ideal substrate for printed circuit boards (PCBs). The “FR” in FR4 stands for “flame retardant,” signifying its ability to resist combustion, a critical safety feature in electronic components.

The Density of FR4: A Key Parameter

The density of FR4 is typically around 1.850 g/cm³, although slight variations may occur due to manufacturing processes. This parameter is crucial because it reflects the material’s uniformity, compactness, and overall quality. A higher density indicates a more uniform and compact structure, which, in turn, suggests better mechanical properties and quality. However, it’s essential to note that while density can hint at the material’s quality, the insulation properties depend on other factors, such as the breakdown voltage and dielectric loss factor.

Why is FR4 Density Important in Electronics?

The density of FR4 plays a vital role in electronics for several reasons. Firstly, it affects the PCB’s mechanical strength and durability, ensuring the board can withstand the physical stresses of assembly and use. Secondly, a uniform density across the board facilitates consistent electrical performance, reducing the risk of circuit failures. Lastly, the thermal properties of FR4, such as its ability to dissipate heat, are influenced by its density, affecting the overall reliability of the electronic device.

Applications of FR4

FR4’s versatility and superior properties make it suitable for a wide range of applications in the electronics industry. It is predominantly used as the substrate material for PCBs found in various electronic devices, from consumer electronics like smartphones and computers to industrial and automotive electronics. The material’s flame retardant nature and excellent electrical insulation capabilities also make it ideal for use in electrical insulators, transformers, and other components requiring high mechanical strength and thermal stability.

FR4 stands as a cornerstone in the electronics manufacturing industry, offering an unparalleled blend of mechanical strength, electrical insulation, and thermal stability. Its density, a critical quality attribute, plays a significant role in determining the material’s suitability for various applications, impacting the performance and reliability of electronic devices. As technology continues to advance, the importance of materials like FR4, capable of meeting the stringent demands of modern electronics, cannot be overstated.

In the ever-evolving landscape of electronics, FR4 remains a material of choice for those seeking to balance cost, performance, and reliability, underscoring its enduring relevance and importance.

More: