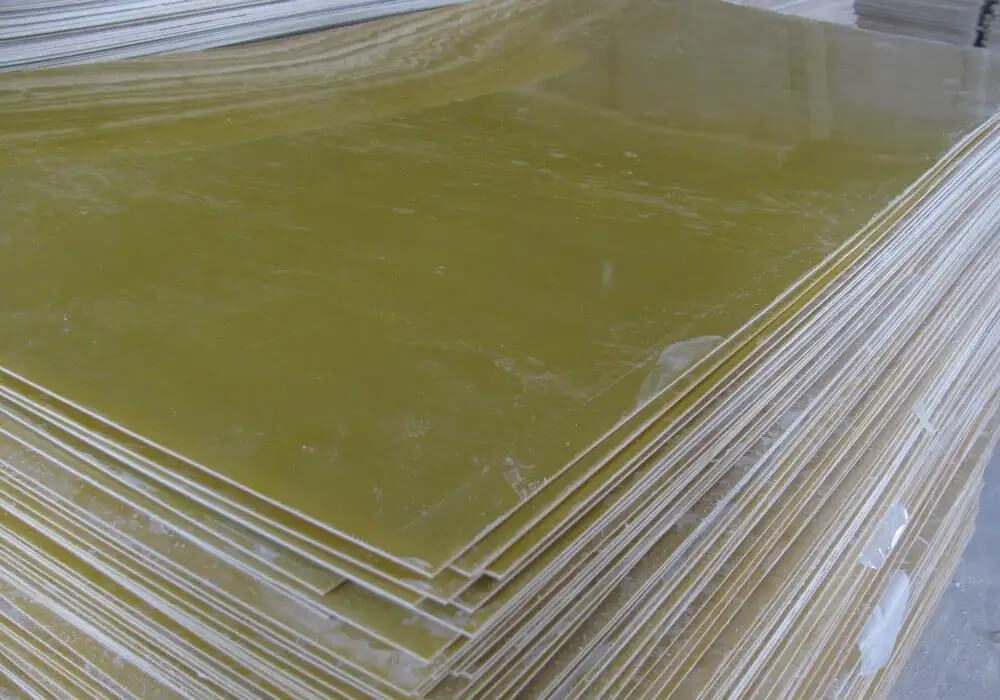

“No Flow Prepreg” has emerged as a significant innovation in the realm of composite manufacturing, offering unique characteristics that contribute to enhanced efficiency and precision. This article delves into the applications and recent advancements surrounding it, shedding light on its pivotal role in shaping the future of composite materials.

1. Understanding No Flow Prepreg:

Define the composition and distinctive features of it.

Explore how its formulation differs from traditional prepreg materials.

2. Applications Across Industries:

Investigate the diverse applications of it in various industries.

Highlight its role in aerospace, automotive, sports equipment, and other advanced composite applications.

3. Advancements in Manufacturing Techniques:

Explore recent innovations in the manufacturing processes of it.

Discuss how advancements contribute to improved product quality and consistency.

4. Enhanced Precision and Control:

Discuss how it provides enhanced precision during composite layup.

Explore its role in intricate designs and complex geometries.

5. Impact on Composite Mechanical Properties:

Examine how the use of No Flow Prepreg influences the mechanical properties of composite materials.

Discuss its contributions to strength, flexibility, and overall performance.

6. Environmental Considerations:

Investigate the environmental aspects of No Flow Prepreg, including recyclability.

Discuss how it aligns with sustainability goals in composite manufacturing.

7. Challenges and Solutions:

Address challenges associated with the use of No Flow Prepreg in manufacturing.

Highlight solutions and ongoing research to overcome limitations.

8. Comparative Analysis with Traditional Prepregs:

Compare the properties and performance of No Flow Prepreg with traditional prepreg materials.

Discuss scenarios where No Flow Prepreg offers distinct advantages.

9. Future Trends and Industry Adoption:

Speculate on the future trends of No Flow Prepreg in composite manufacturing.

Discuss its potential for widespread adoption across industries.

10. Collaborative Research and Development:

Highlight collaborative efforts and partnerships driving research and development in No Flow Prepreg technology.

Discuss how industry collaboration contributes to innovation.

“No Flow Prepreg” stands as a transformative element in the evolution of composite materials, promising increased precision, efficiency, and versatility in manufacturing. Exploring its applications and advancements provides valuable insights for industries seeking to push the boundaries of what is achievable with advanced composites.

More: