The manufacturing process of copper clad laminate (CCL) plays a crucial role in producing the foundation for high-performance printed circuit boards (PCBs). This article provides a comprehensive exploration of the steps involved in the manufacturing process, offering insights into the intricate procedures that contribute to the creation of top-tier PCB substrates.

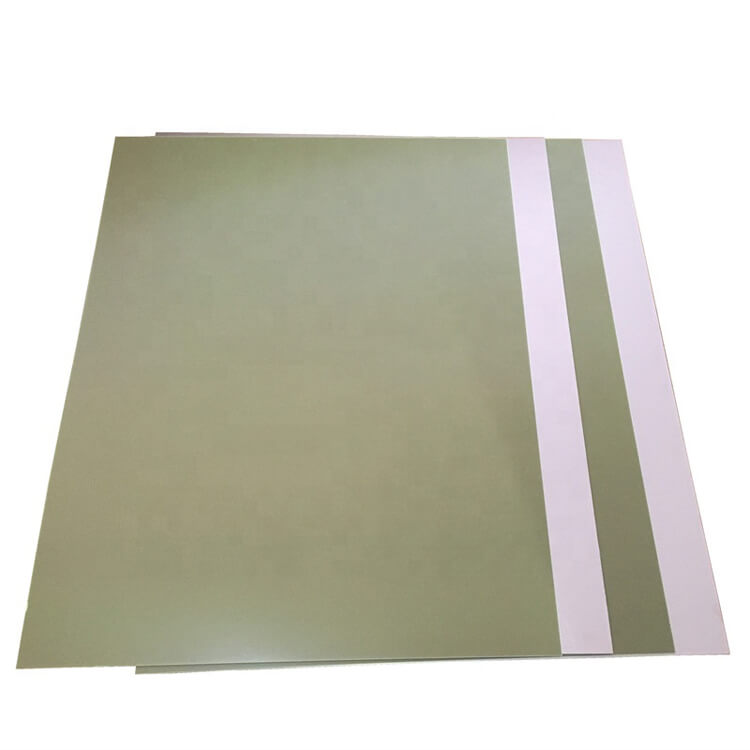

1. Raw Material Selection:

Explore the key raw materials used in copper clad laminate manufacturing.

Discuss the importance of selecting high-quality base materials for optimal performance.

2. Substrate Preparation:

Detail the preparation steps for the substrate, including cleaning and surface treatment.

Discuss how substrate preparation influences the adhesion and performance of the copper layer.

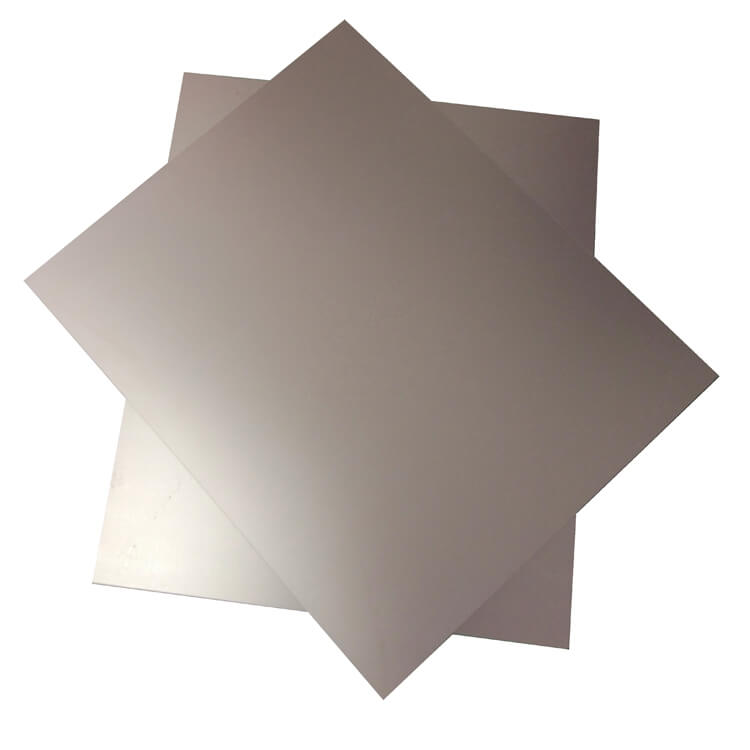

3. Copper Foil Lamination:

Explain the process of laminating copper foil onto the substrate.

Explore variations in lamination techniques and their impact on conductivity.

4. Pressing and Bonding:

Discuss the pressing and bonding steps in copper clad laminate manufacturing.

Explore the parameters influencing the bonding process for uniformity and strength.

5. Resin Impregnation:

Explore the resin impregnation process to ensure uniform distribution.

Discuss the role of resin in providing insulation and mechanical support.

6. Curing and Pre-Curing:

Detail the curing process to harden the resin and strengthen the laminate.

Discuss pre-curing steps to set the foundation for subsequent processes.

7. Drilling and Pattern Formation:

Explore the drilling process to create holes for component placement.

Discuss the formation of patterns using precision techniques.

8. Surface Treatment:

Detail the surface treatment steps for improved solderability and adhesion.

Discuss the application of protective coatings for enhanced durability.

9. Quality Control Measures:

Highlight the importance of quality control measures throughout the manufacturing process.

Discuss testing methods to ensure adherence to industry standards.

10. Environmental Considerations:

Explore environmentally friendly practices and innovations in CCL manufacturing.

Discuss the industry’s efforts to reduce waste and energy consumption.

Understanding the intricacies of the copper clad laminate manufacturing process is essential for producing high-quality PCB substrates. Navigating through each step provides valuable insights into the precision and care required to create the foundation for advanced electronic devices.

More: