FR-4 is a code name for a flame-resistant material grade. It means a material specification of which the resin material must be self-extinguishing after being burned. It is not a material name, but a material grade, There are many types of FR-4 grade materials used in the board at the current moment, but most of them are composite materials made of so-called four-function (Tera-Function) epoxy resin plus filler (Filler) and glass fiber.

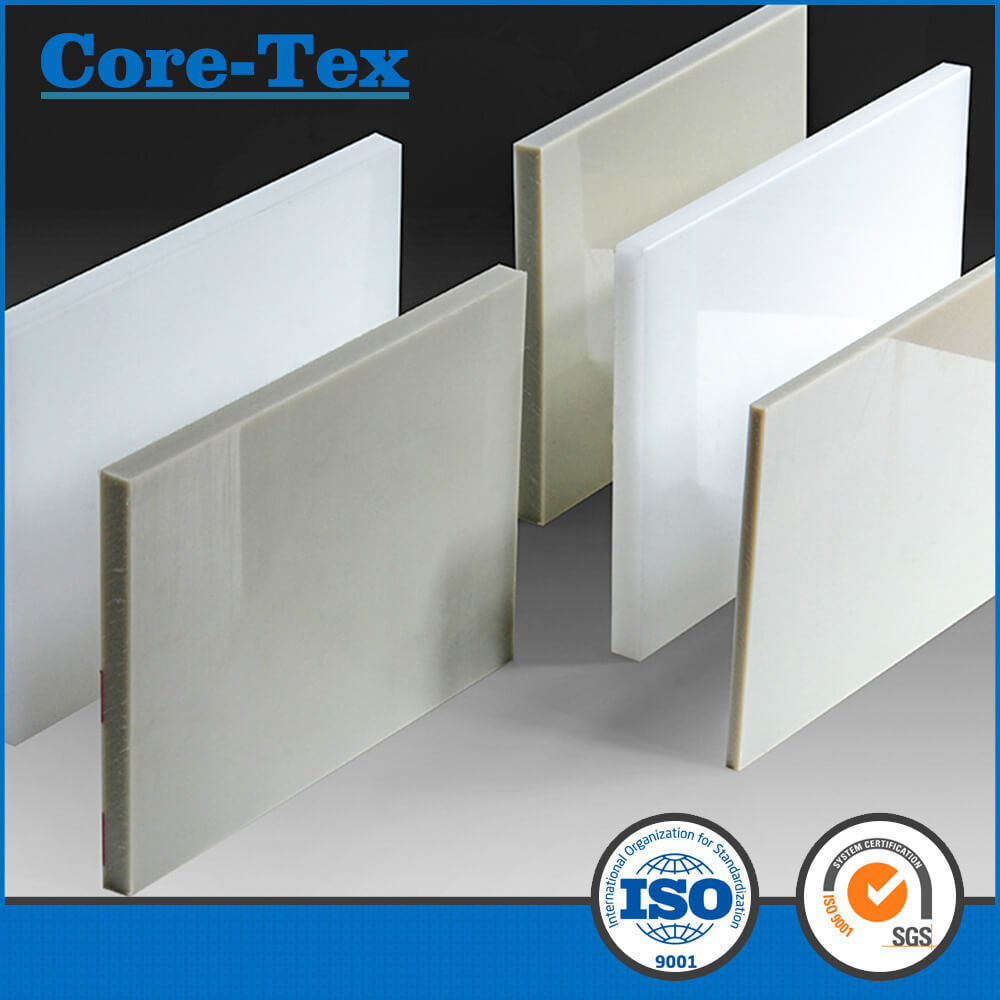

To make fr4 epoxy fixtures ,Let us first understand the characteristics of the fr4 epoxy board: fr4 epoxy board is a kind of substrate with epoxy resin as adhesive and electronic grade glass fiber cloth which was used as a reinforcing material.

Its bonding sheet and inner core thin copper clad plate are important substrates for making multilayer printed circuit boards. The mechanical properties, stability dimensional, impact resistance and moisture resistance of the fr4 epoxy board are higher than those of the paper substrate. Its electrical performance is excellent, its operating temperature is high, and its performance is less affected by the environment. In terms of processing technology, it has great advantages over other resin fiberglass cloth substrates. These products are mainly used for double-sided pcbs and are used in large quantities. Epoxy fiberglass cloth substrate, the most widely used product model is FR-4. In recent years, due to the development of electronic product installation technology and PCB technology, high Tg fr4 products have appeared.

The fr4 epoxy clamp is a device used in the mechanical manufacturing process to fix the object to be in the correct position for construction or inspection. Also known as fixtures.

Broadly speaking, any device which can be used quickly, conveniently, and safely mount a workplace during any process in the process can be referred to as a fixture. For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc. Among them, machine tool fixtures are the most common, often referred to as fixtures. When machining a workplace on a machine tool, in order to achieve the technical requirements of the dimensions of the workplace, the workplace must be mounted (positioned) and clamped (clamped) before machining. . The fixture usually consists of a positioning element (determining the correct position of the workplace in the fixture), a clamping device, a tool guiding element (determining the relative position of the tool and the workplace), and an indexing device (making the workplace in one installation) It can complete the processing of several stations, including two types of rotary indexing devices and linear moving indexing devices, connecting components and clips (clamp base).