When Non-flow prepreg is applied to the rigid-flex joint plate and the cold plate, neither the cold plate window region nor the junction of the rigid-flex joint plate is intended to flow excessively. But it is necessary for the basic flow-fill line when pressing. From the rheological point of view, that is, resin melting and bonding surface, as long as the air to the edge, no longer flow. As the joining material of the rigid-flex joint plate and the step plate, Non-Flow prepreg is not truly “non-flow” from the viewpoint of the resin melt viscosity curve of Non-Flow prepreg. Since Non-Flow prepreg also has a certain degree of liquidity when it be pressed, then liquidity is whether like ordinary FR-4 prepreg or not, the flowing glue of the board edge is bigger than the middle position of the board ?

SP120N and V two kinds of Non-Flow prepregs were used to conduct comparative experiment, and investigate the flow glue in different positions of the plate. Experimental designing structure, such as: 1 × PI film + 1 × 1080 (RC=64%) + 1 × electrolytic copper.

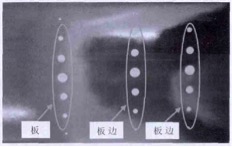

After laminating the PI film and the Non-Flow prepreg, poles were punched in different positions of the sample using a punch, as shown in Fig. 12 and 13.

Fig.12 Punching Pole Graphics(Unit:mm)

Fig.13 Experimental Punching Pole Position

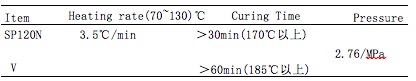

Then PI film、Non-Flow prepreg and the copper foil were laminated to form a test and pressed. Pressing conditions, as shown in Table 6.

Table 6 Pressing Conditions

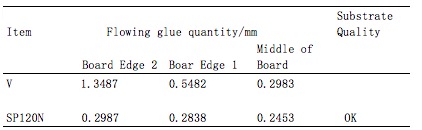

The flowing glue quantity of Non-Flow prepreg after laminated was measured, as shown in Table 7.

Table 7 Flowing glue quantity of board

From the above test results, there is a difference in the amount of flowing glue between the edge and the middle position of the plate after laminating non-flow prepreg; the amount of glue in the edge position after pressing V material is far greater than the middle position; After pressing SP120N prepreg, the edge and the middle flow glue quantity is small, only has little difference.

Conclusion

Non-Flow prepreg has a very low flowability, which is obviously different from the ordinary FR-4. Based on the above analysis, the characteristics of non-flow prepreg are as follow:

Because it is not easy to drop out of powder for Non-Flow prepreg, GT index can not be used to judge the high temperature resin curing fluidity of Non-Flow prepreg. To monitor the quality of the non-flow prepreg, a test method of non-flow prepreg resin fluidity is required;

Although the non-flow prepreg has “no flowability”, with the increase of the heating rate during the test, the resin melt viscosity curve of the non-flow prepreg becomes wider and the minimum melt viscosity becomes smaller, and the fluidity of the resin also becomes large.

As the non-flow prepreg of the joint material, it need pay more attention to the machinability during opening windows operation. SP120N Non-Prepreg’s hole wall has good quality ,without hole wall whitening phenomenon after punching the hole; ordinary FR-4 material’s hole wall appeared glass yarn crack and hole wall whitening phenomenon after punching holes.

From the R & D principle, the Non-Flow prepreg is epoxy system, Non-Flow Prepreg’s pressing way can not simply apply pure prepreg’s fast-pressing way and ordinary FR-4’s pressing way, otherwise easily lead to board layer blast because of material curing is insufficient.

Non-Flow prepreg also has a certain degree of liquidity when it be pressed, there is a difference in the amount of flowing glue between the edge and the middle position of the plate. The flowing glue quantity is different when different Non-Flow prepreg of different manufacturers were pressed.

Discussion on the features of No-Flow prepreg.pdf

Discussion on the features of No-Flow prepreg.pdf