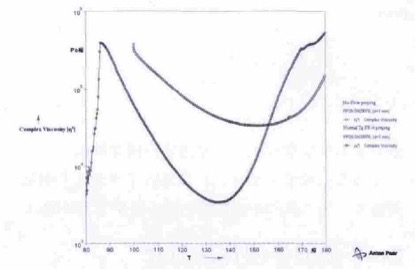

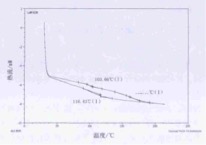

“No-flow” is the largest characteristic of the Non-Flow prepreg. This kind of plate has strict requirements to the flow ability of Non-Flow prepreg, to prevent flowing glue in the rigid-flex joint, the step slot, etc..From the melt viscosity curve of view of Non-Flow prepreg and conventional ordinary FR4 prepreg, the melt viscosity of the Non-Flow prepreg is higher than that of the ordinary FR-4, and the lowest melt viscosity is 10-100 times higher than that of the ordinary FR-4, as shown in Fig.

Fig 2 Resin melt viscosity curve comparison chart of Non-Flow prepreg and conventional ordinary FR4 prepreg

In addition, since Non-Flow prepreg often require opening window operations, the Non-Flow prepreg must have good toughness and machinability.

Discussion on the features of No-Flow prepreg

Since Non-Flow prepreg has bigger difference from the ordinary FR-4 prepreg, the experience of the ordinary FR-4 prepreg can not be simply applied when Non-Flow Prepreg is used. This paper analyzed and discussed the characteristics of Non-Flow Prepreg from the aspects of Non-Flow Prepreg index, melt viscosity curve, glass transition temperature curve, mechanical processing and press-fit method.Some suggestions were provided for the application of Non-Flow Prepreg.

Non-Flow Prepreg index

GT is an important index to evaluate the fluidity of ordinary FR-4 prepregs at high temperature. Prolong GT of prepreg can increase resin flow ability at high temperature, thus enhancing resin’s wetting and filling capacity. However, Non-Flow Prepreg is not easy to fall out of powder, and the fluidity of the resin at high temperature can not be judged by the GT. To this end, it was established test method of Non-Flow Prepreg’s resin fluidity in IPC-TM-650.

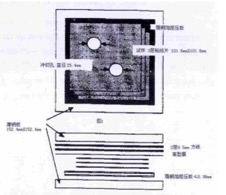

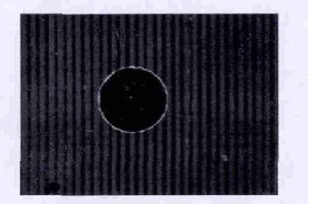

As shown in Fig.3, two 1-inch holes were punched in the sample, the sample、laminated board、release film and pad were placed in two thin steel sheet, and the laminate was placed on a sheet maintained at 171℃±2.8 ℃ in the pressing machine, Immediately clamping mold and make pressure to 1380kPa±70kPa. After at least 20 min at full pressure, remove the pressure and remove the laminate.

Fig 3 Test method for excess glue

After the resin flowed, the diameter of the hole became small, and measured the diameter of the hole. The hole average diameter when punched, subtract the hole diameter after pressing, that is Non-Flow Prepreg’s resin fluidity, the unit is mm.

The Resin Melt Viscosity Curve at Different Heating Rate

When the melt viscosity curve of ordinary FR-4 material was tested, the melt viscosity curve became wider and the lowest melt viscosity became smaller as the heating rate increased. “No flow” is the largest flow characteristics of Non-Flow Prepreg, Whether the resin melt viscosity curve of Non-Flow Prepreg has the same law or not ?

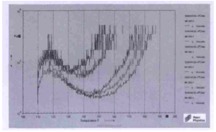

Select SP120N, the resin melt viscosity curve when testing different heating rate.As shown in Fig 4.

Fig 4 the resin melt viscosity curve in different heating rate

From Fig. 4, the melt viscosity curve of the Non-Flow Prepreg is widened and the lowest melt viscosity becomes smaller as the temperature rise rate was increased during the test. Therefore, although Non-Flow Prepreg has “non-fluidity”, the resin fluidity of the Non-Flow Prepreg will increase as the temperature rise rate was increased.

Glass transition temperature curve

The earliest non-flowing prepreg was a thermoplastic rubber-filled epoxy system or an epoxy system synthesized from partially cross-linked acrylic acid. With the advancement of technology, “non-fluidity” is before the material in the formation of B-order form, It is achieved through chemical way to control molecular weight distribution.Choosing SP120N and a company’s V material,and they were pressed into sheet separately,then test the glass transition temperature of the sheet. The results are shown in Table 1.

Table 1 Tg Test Result

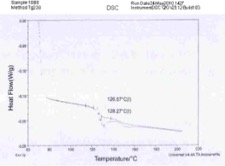

Glass transition temperature test curve,As shown in Fig.5,Fig.6.

Fig.5 SP120N Tg test curve

Fig.6 V material test curve

From above test results, SP120N’s Tg test curve has only a Tg test peak, but V material Tg test curve appeared Tg double peaks phenomenon.

Non-Flow prepreg mechanical processing

In the combination of cooling plate and PCB, due to the different shape of PCB and cooling plate, opening window area often have components, cooling plate window position does not want any resin outflow. As the Non-Flow prepreg of connecting material, it is necessary to pay attention to the machinability during opening window operation. If the edge of the window position for Non-Flow Prepreg has crack, because of its poor fluidity, where prone to substrate cracks and voids, there is the risk of stratification.

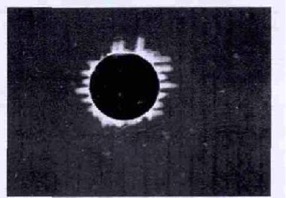

Choosing 1080 prepreg with SP120N and ordinary FR4 material , using the same punching tools and parameters, have punching test and assess the hole wall quality. As shown in Fig. 7, Fig. 8.

Fig.7 SP120N(1080 prepreg)hole wall quality

Fig.8 Ordinary FR4 material(1080 prepreg)hole wall quality

From the above test results, SP120N Non-Prepreg’s hole wall has good quality ,without hole wall whitening phenomenon after punching the hole; ordinary FR-4 material’s hole wall appeared glass yarn crack and hole wall whitening phenomenon after punching holes.

More products informations, please contact [email protected], we have a specialized technical engineers service for you, at the same time we can offer you free samples.