From the R & D principle, the Non-Flow prepreg is epoxy system modified, by adding a low-flow polymer in the formula, through B-order chemical reaction to reduce the fluidity of the product itself. The early as rigid-flex board and step board’s connecting material -pure prepreg, mainly is the acrylic system materials. As the two materials’reaction system is not same, Non-Flow Prepreg’s pressing way can not simply apply pure prepreg’s fast-pressing way, otherwise easily lead to board layer blast because of material curing is insufficient.

Fast-Pressing Method

The comparison of the experimental results with SP120N was carried out using fast pressing (Table 2) and fast heating pressing bonding (Fig. 9). The board structure was 3 × 1080 (RC = 64%) + CCL substrate (e.g.S1000-2).

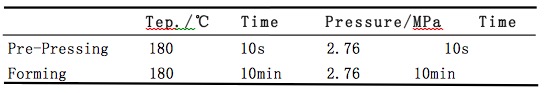

Tale 2 Pressing Way

Note: Heat-up rate:3.0-5.0℃/min(70-130℃)

Cure time: >30min(170-180℃)

Note: Heat-up rate:3.0-5.0℃/min(70-130℃)

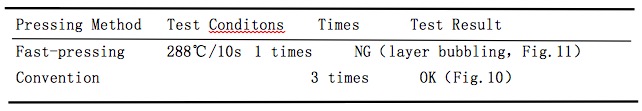

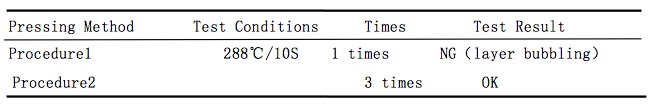

The heat resistance of the materials was measured under the two kinds of pressing methods.The results are shown in Table 3. Fig. 10 and Fig.11.

Table 3 The Heat Resistance Test Result

Fig.10 SP120N Substrate OK

Fig.11 SP120N Substrate layer bubbling

From the above experimental results, SP120N Non-Flow Prepreg’s compression method can not simply apply pure prepreg’s fast-pressing method, otherwise easily lead to heat resistance became deteriorated because of material curing is insufficient.

Special Pressing Method

According to the flow curve of the resin melt viscosity for Non-Flow Prepreg and the ordinary FR4 prepreg,we can see the melt viscosity of the Non-Flow prepreg is higher than that of the ordinary FR-4, and the lowest melt viscosity is 10 to 100 times higher than that of the ordinary FR-4, and the melt viscosity of the Non-Flow Prepreg is higher than that of the conventional FR-4.In order to better wetting and bonding, must provide high pressure, otherwise easily to cause cavity of Non-Flow prepreg.

The contrast experiment of the different compression procedure was carried out with SP120N.The structure of the board was as follows: 3 × 1080 (RC = 64%) + CCL Substrate (e.g.S1000-2).

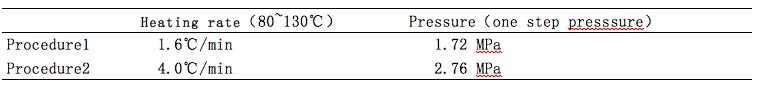

The parameters of the lamination program are shown in Table 4.

Table 4 Heating rate verification test

The heat resistance of the material under both pressing procedures was tested. The results are shown in Table 5.

Table 5 The Heat Resistance Test Result

From the above experimental results, because SP120N Non-Flow Prepreg has low fluidity, the method is different from the ordinary FR-4 material, and can not simply apply the ordinary FR-4 material compression method, otherwise easily lead to heat resistance became deteriorated because Non-Flow prepreg and bonding interface’s cavity.

More products informations, please contact [email protected], we have a specialized technical engineers service for you, at the same time we can offer you free samples.

Discussion on the features of No-Flow prepreg.pdf

Discussion on the features of No-Flow prepreg.pdf