The world of electronics is vast, and its rapid growth is fueling an increasing demand for high-quality insulating materials. One such critical material is FR4, a flame-retardant laminate commonly used in the manufacturing of circuit boards. In this context, FR4 manufacturers are a pivotal part of the electronics supply chain.

The global market offers a multitude of choices, from Asia-based providers to European and American manufacturers. Each has its advantages in terms of pricing, quality, and lead times. For instance, Asian manufacturers may offer competitive prices, but European and American suppliers often boast stringent quality control. When navigating the global landscape, it’s essential to consider these factors alongside logistical considerations like shipping time and customs duties.

The Role of FR4 Manufacturers in the Growing Electronics Industry

The electronics industry is growing at an unprecedented rate. From smartphones and tablets to IoT devices and electric vehicles, the application of electronic components is expanding. Here, FR4 manufacturers play an indispensable role by providing reliable and durable materials that meet the evolving needs of the industry. High-quality FR4 laminates are essential for ensuring that electronic devices are both functional and safe. As trends like miniaturization and high-frequency applications continue to evolve, the role of FR4 manufacturers becomes even more critical in offering innovative solutions for complex designs and applications.

FR4 Manufacturers vs. Alternative Material Providers: A Comparative Analysis

While FR4 is the industry standard for most PCB applications, there are alternative materials like G10 and G11, as well as ceramics and metal-core boards. Here’s a quick comparison:

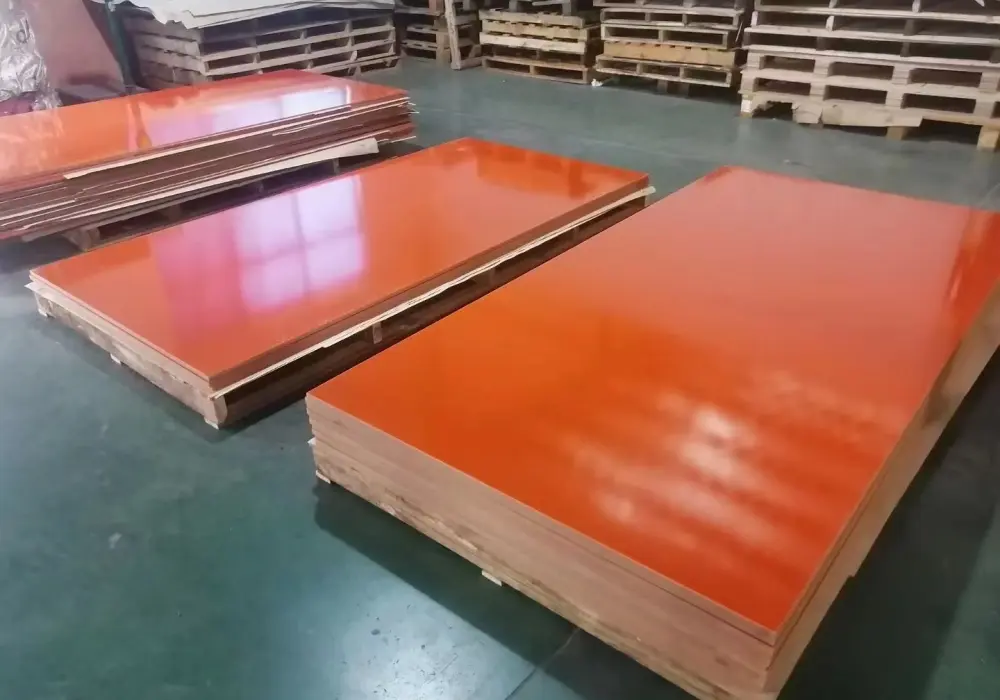

- FR4: Offers excellent electrical insulation, high mechanical strength, and flame resistance. Ideal for a wide range of applications.

- G10: Less expensive than FR4 but lacks flame retardancy. Suitable for applications where fire resistance is not crucial.

- G11: Similar to FR4 but offers higher temperature resistance. Suitable for extreme conditions.

- Ceramics: High temperature and electrical insulation but can be brittle and expensive.

- Metal-core: Excellent for heat dissipation but generally costlier and heavier.

Each material has its place, and the choice often depends on the specific requirements of your project. FR4 manufacturers often also offer G10 and G11 options to cater to different needs.

Key Factors to Evaluate When Choosing an FR4 Manufacturer

When you’re looking to source FR4 materials, several key factors can make your selection process more straightforward:

- Quality Control: Look for manufacturers with ISO certification and rigorous QC processes.

- Pricing: Competitive pricing is essential, but remember that you often get what you pay for in terms of material quality.

- Lead Time: Consider how quickly the manufacturer can deliver, especially if you have tight deadlines.

- Customer Service: Efficient and effective customer service can save you a lot of time and effort, especially if custom solutions are needed.

- Sustainability: In a world increasingly focused on sustainability, look for manufacturers that are making efforts to reduce their environmental impact.

FR4 manufacturers play a critical role in the electronics industry. When navigating this landscape, be mindful of quality, price, and your specific needs to find the right manufacturer for your project.

For more information on FR4 and other insulating materials, visit our website FR4 Material.