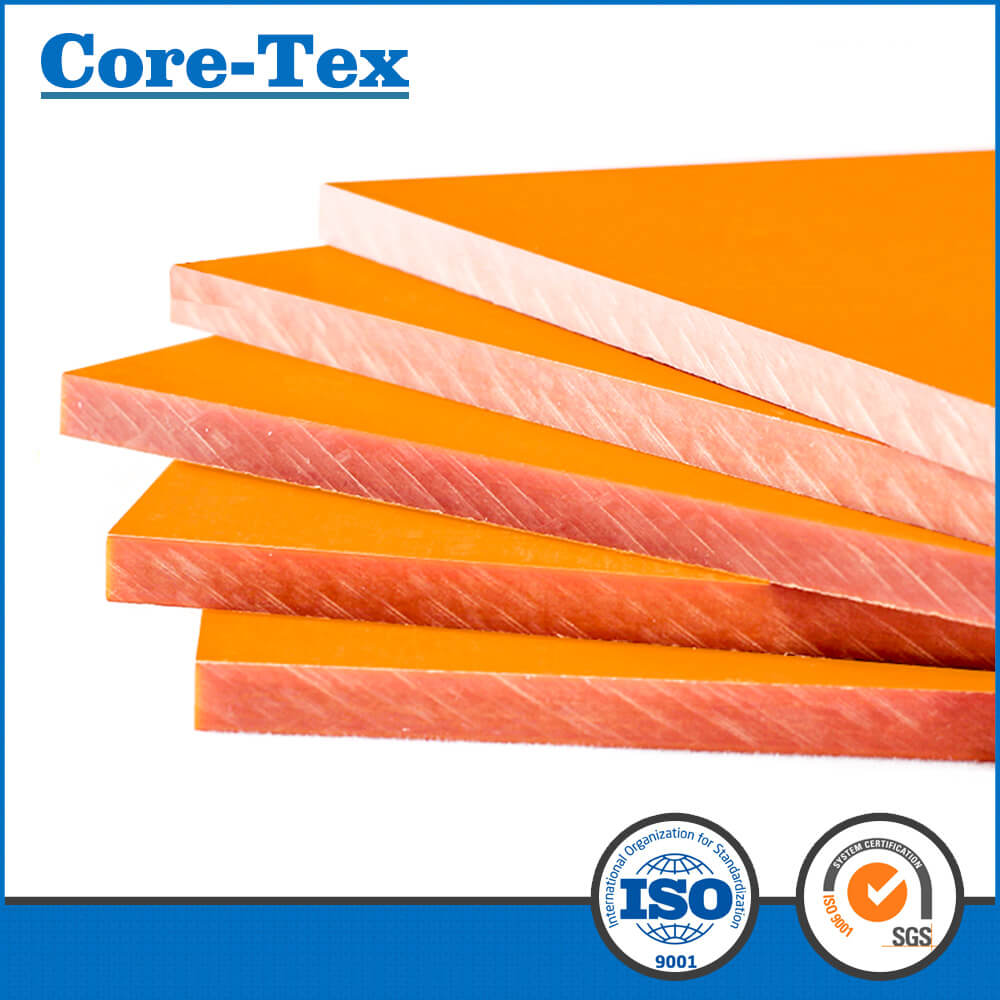

1. Perfect uniform layers

The epoxy board floor: The resin composite with fiberglass, the layers are uniform. It will not be drummed or delaminated due to the influence of groundwater vapor or ground cracks, which completely solves the technical defects.

2. Excellent physical and chemical properties

The products are manufactured by machinery and are not affected by ambient temperature, humidity, and human factors, ensuring quality stability. Due to the high curing temperature and high curing density, the physical and chemical properties of the product are superior to the traditional epoxy floor paint. The service life of the product is greatly improved, and the service life under normal conditions is more than ten years.

3. Easy installation and maintenance

The installation period is short and the speed is fast. The installation capacity per person per day can reach more than 200 square meters. The installation process is safe and tasteless, and it can be put into use after installation. The installation does not affect the normal production of the enterprise.

4. Cost-effective

The long service life reduces the cost of the floor, and it’s easy to install, and the extremely maintenance the normal production of the enterprise, avoiding direct and indirect economic losses due to frequent floor maintenance during the production process.

The products have passed the international environmental protection certification, and all environmental protection indicators have reached international standards. The production and installation process is non-toxic.

At present, GREP has been widely used in textile and garment, food and medicine, machinery and electronics, chemical manufacturing and other industries.