Fr4 insulation laminate does not contain harmful asbestos. It has high mechanical and dielectric properties, good heat resistance and moisture resistance, and good processability, low thermal conductivity, high temperature resistance up to 250 ℃ (220℃, 300℃), high flatness, excellent bending strength at high temperatures.

It is used in plastic molds, injection molds, rubber injection molds, vulcanizers, molding machines, hydraulic presses, machinery manufacturing, injection molding machines, hot pipe systems, motors, silicone molds, magnesium, zinc, aluminum alloy die-casting mold, etc. General engineering, electrical appliances, solar power plants, etc.

Injection molding usually requires: high temperature materials and low temperature molds. Keeping the injection mold at low temperature does not make the temperature of the injection molding machine too high. This requirement can be met by installing an insulating insulation panel between the injection molding and the injection molding machine. Shorten production cycle, increase productivity, reduce energy consumption, improve finished product quality, continuous production process ensures product quality is stable, prevents machine overheating without electrical failure, no leakage of hydraulic system. It is widely used for rubber mold factory, injection mold factory, plastic mold factory, injection molding machine factory, solar power plant, machinery factory, shoe mold factory.

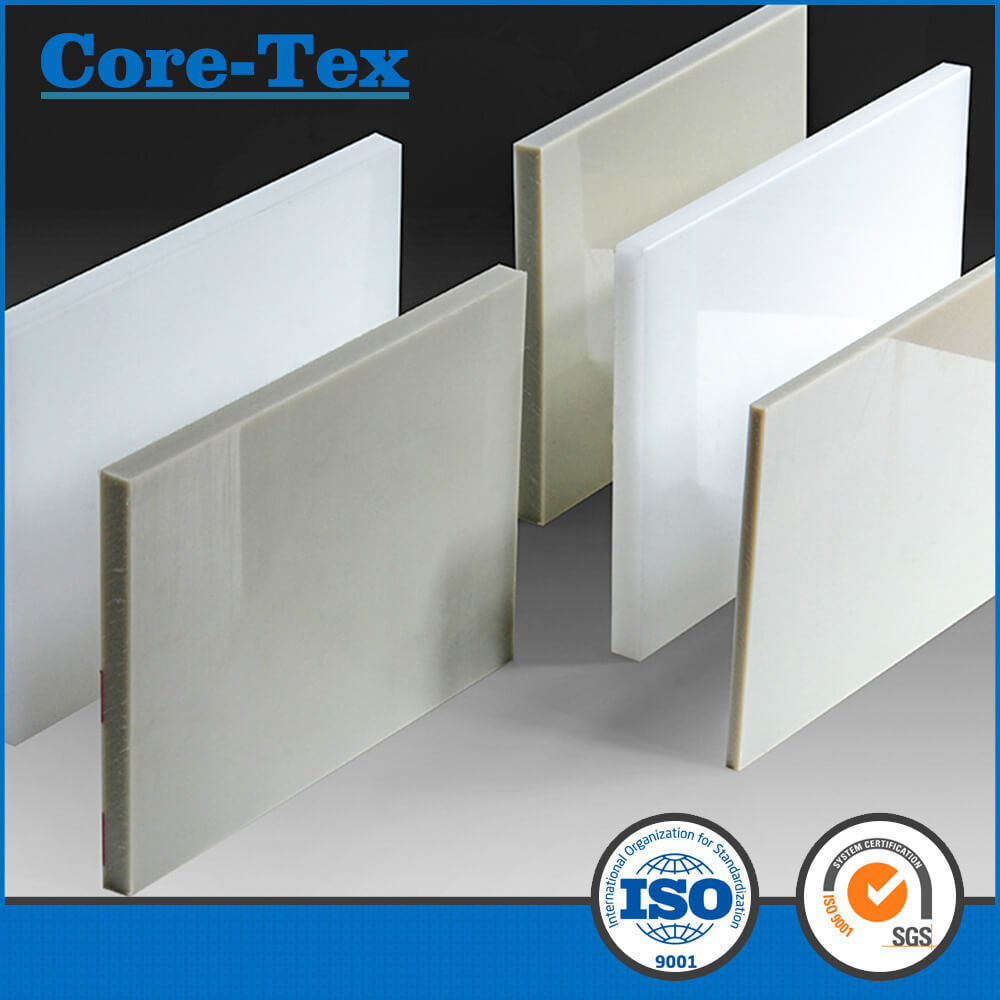

Thickness: 2.0mm-50mm

Width: 1150mm

Length: 1250mm

Technical data:

1. Working temperature: ℃ 220 250.

2. Bending strength 23℃(normal temperature): Mpa 210 210

3. Compressive strength 23℃(normal temperature): Mpa 600 600

4. Compressive strength 200℃(working temperature): Mpa 500 500

5. Transverse heat conduction: W/M.K 0.27 0.27

6. Linear expansion coefficient: 10-6/K 10-15 10-15

7. Water absorption rate: % <0.2 <0.2

8. Density / specific gravity: g/cm3 2.0 2.0

9. Thickness tolerance mm: mm -0.1 +0.1