A short video about us

View Our Main Products

Our company integrates production, research and development and deep processing, and is committed to providing continuous and effective product solutions for high-end electronic basic materials and special composite materials applications.

G3 Sheet is a kind of laminated sheet formed through heat pressing after the electric industry fiberglass cloth dips into epoxy resin.Suitable as the mechanical.

G9 sheet is made of alkali-free glass cloth impregnated with melamine formaldehyde resin by drying and hot pressing.

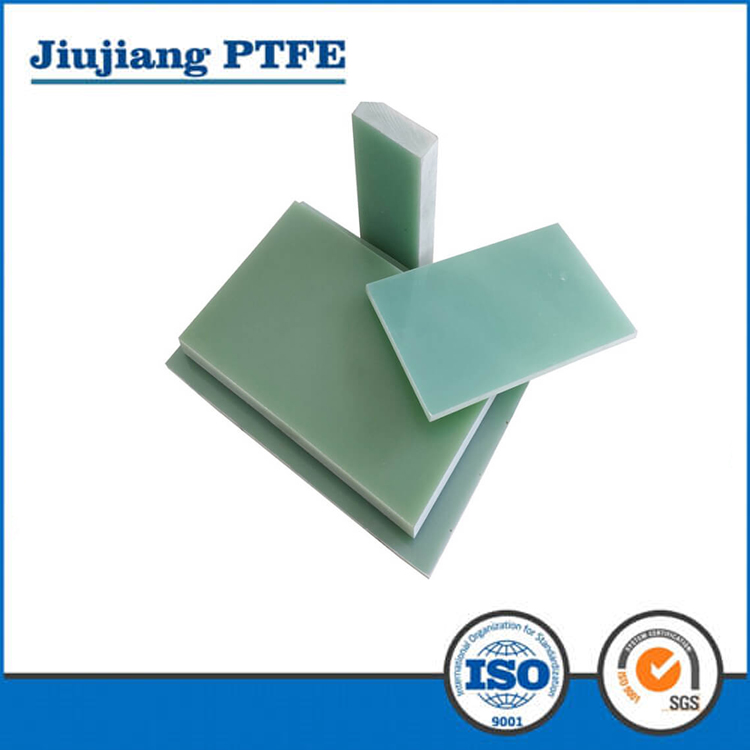

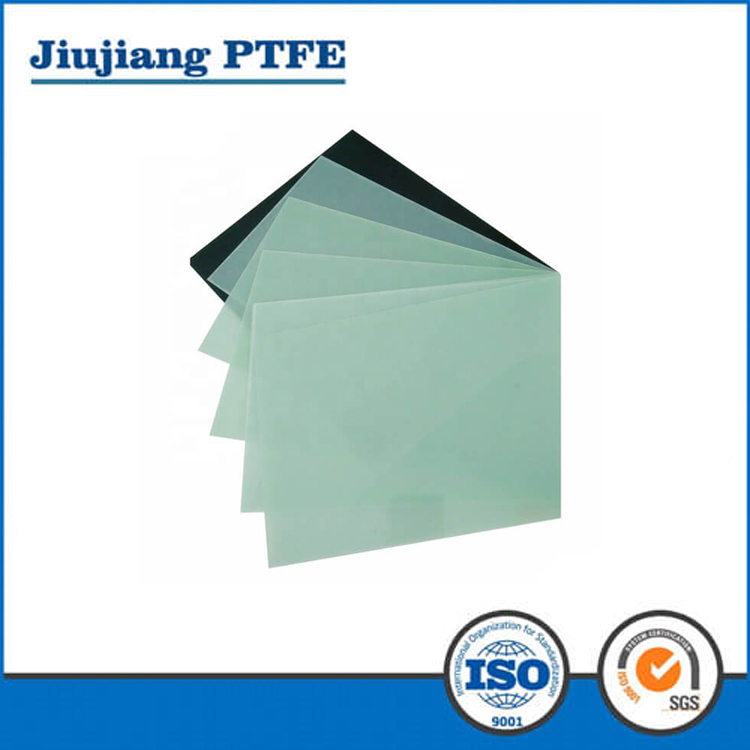

G10 sheet is made of glass fiber cloth for electronics impregnated with brominated epoxy resin and heated and pressurized.

G11 sheet is a composite material composed of woven fiberglass cloth and brominated flame retardant with an epoxy resin binder.

Suitable as the mechanicaland electronic insulation structural components which are used under homoeothermy and middle temperatures with a certain mechanicaland electric performance.

FR3 sheet is widely used in MCB series circuit breakers and H-class high temperature resistant electrical insulating materials for various electrical equipment.

Widely used in motors and electrical equipment, various switches, electrical insulation, FPC reinforcement boards, carbon film printed circuit boards, computer drilling pads, mold fixtures, etc.

High mechanical properties, dielectric properties and flame retardant properties, good heat resistance and moisture resistance, and good machinability.

3240 Epoxy Phenolic sheet is made of electrician alkali-free glass cloth impregnated with epoxy phenolic resin by hot pressing.

3233 sheet is a composite material composed of woven fiberglass cloth and brominated flame retardant with an epoxy resin binder.

3242 sheet is made of chemically treated electrical alkali-free glass fiber cloth as the base material and epoxy resin as the adhesive by hot pressing.

3248 sheet has high mechanical strength at high temperature and stable electrical performance under high humidity.

It fully meets the requirements of EU RHOS standards and SGS standards,widely used in products which requiring high-performance electronic insulation.

It has high mechanical properties, dielectric properties and flame retardant properties, good heat resistance and moisture resistance.

This laminate sheet is made of alkali-free glass fiber cloth for electrical as the base material and high TG epoxy resin as the adhesive by hot pressing.

This sheet is made of non-alkali glass fiber cloth impregnated with special epoxy resin through high temperature and high pressure.

View Other Interesting Products

Based on the business promotion concept of “R&D-oriented, quality first, delivery time must be reached”, the company has developed step by step into an enterprise with the widest business scope and influential industry in the same kind of epoxy board materials.

FR1 Sheet,commonly known as bakelite plate, phenolic laminated board, which is laminated by phenolic with good bleached wood paper and lint paper.

3250 sheet is made of chemically treated electrician alkali-free glass fiber cloth as the base material and high Tg epoxy resin as the adhesive by hot pressing.

3255 sheet is made by electrician’s special treatment alkali-free glass cloth impregnated with modified diphenyl ether resin by baking and hot pressing.

This sheet is Suitable for the anticorona material in large motor tank,it also can be used as the material for nonmetallic structure parts under high temperature.

308 sheet is widely used in various large-scale generator sets, high-voltage electrical appliances, rail transit, electronic communications fields,etc.

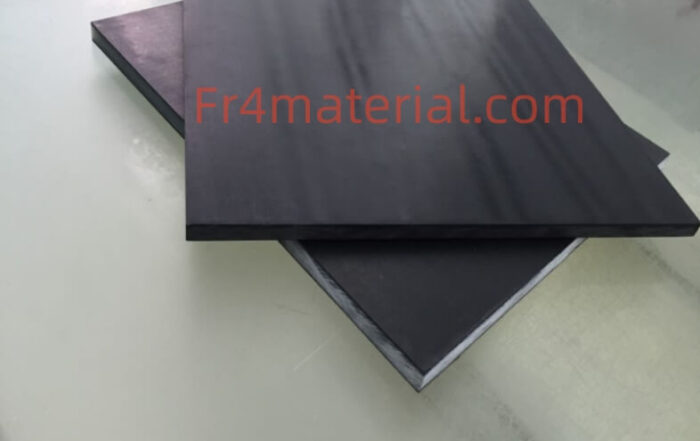

Anti-static Epoxy Glass Cloth Laminate Sheet has anti-static (anti-static) characteristics and good mechanical processing performance.

It is made of alkali-free glass fiber cloth for electricians impregnated with carbon black epoxy phenolic resin by hot pressing.

View Our Latest Articles

In line with our commitment to innovation and industry leadership, we offer a wealth of articles and insights on product applications, industry trends, and technological advancements. Stay informed and connected with the latest developments in the field of high-end electronic materials and special composite materials.

Copper Clad Laminate Manufacturing Process Crafting Quality PCB

The manufacturing process of copper clad laminate (CCL) plays a crucial role in producing the foundation for high-performance printed circuit boards (PCBs). This article provides a comprehensive exploration of the steps involved in the manufacturing [...]

No Flow Prepreg Advancements in Composite Manufacturing

"No Flow Prepreg" has emerged as a significant innovation in the realm of composite manufacturing, offering unique characteristics that contribute to enhanced efficiency and precision. This article delves into the applications and recent advancements surrounding [...]

FR4 Laminated Fiberglass Unveiled: Exploring the Strengths and Applications of Advanced Composite Materials

FR4 laminated fiberglass has become a cornerstone in the world of advanced composite materials, finding widespread use in diverse industries. This article embarks on a journey to uncover the inherent strengths and multifaceted applications that [...]

Resin Coated Copper Foil Unveiled Navigating Applications

Resin coated copper foil has emerged as a key component in modern electronics manufacturing, offering a unique blend of conductivity and protective features. This article delves into the intricacies of it, exploring its diverse applications [...]

Breakdown Voltage of Teflon Electrical Insulation Properties

Teflon, renowned for its exceptional electrical insulation properties, stands out as a key material in numerous high-performance applications. This article delves into the breakdown voltage of Teflon, shedding light on its critical role in ensuring [...]

Decoding Dielectric Constant in FR4 Electrical Insulation Properties

The dielectric constant is a crucial parameter in the realm of FR4 materials, especially in precision electronics. This article unravels the intricacies of the dielectric constant in FR4, shedding light on its significance in providing [...]