First, fiberglass cold stamping sheet (FR4, single-sided, double-sided, multi-layer PCB circuit board, impedance board, blind buried hole board), it is suitable for electronic digital products such as computers and mobile phones.

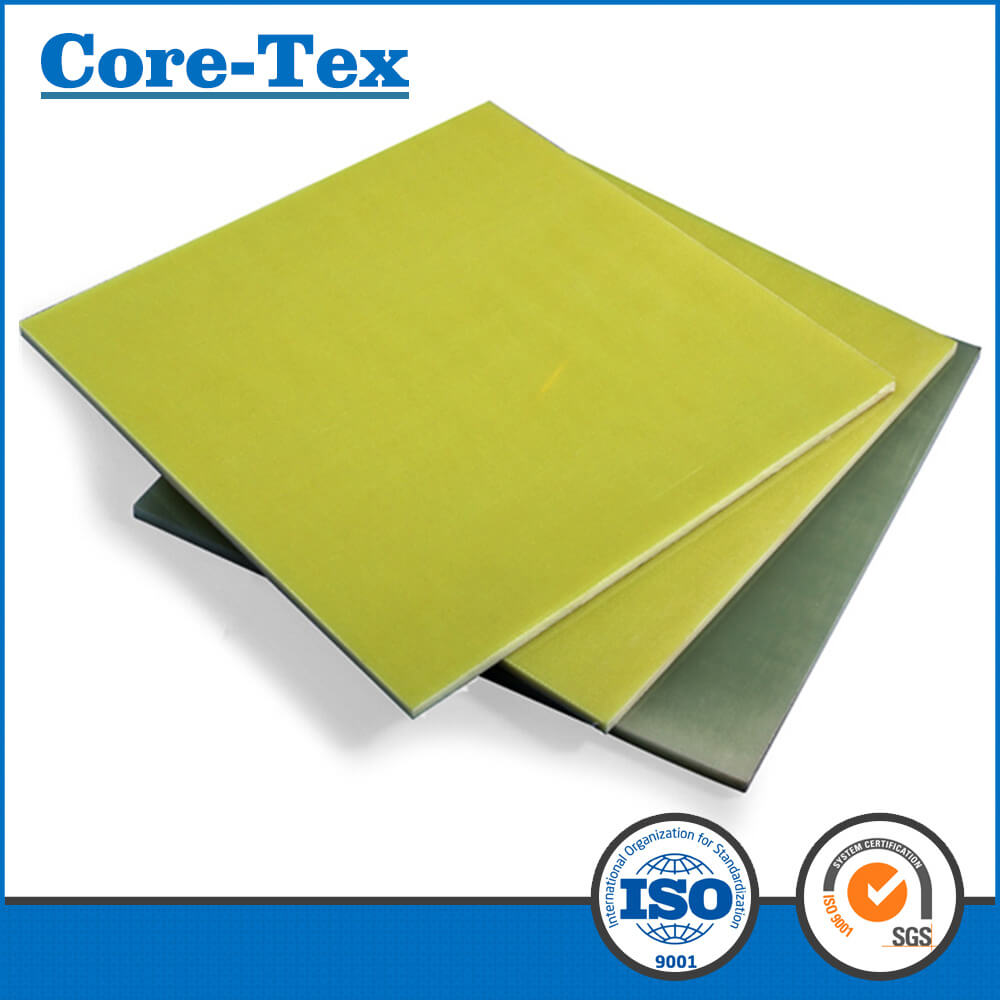

There are many kinds of glass fiber sheet, we will first look together; FR-4 is also known as fiberglass sheet; glass fiber sheet; FR4 reinforcing sheet; FR-4 epoxy sheet; flame retardant insulationsheet, FR4 light sheet; epoxy glass cloth sheet; circuit board drilling pad, generally used for soft-pack base layer, and then cloth, leather, etc., to make beautiful wall and ceiling decoration. The application is very extensive.it has good performance such as sound absorption, sound insulation, heat insulation, environmental protection, flame retardant and so on.

The fiberglass sheet is a composite of epoxy resin plus filler and glass fiber.

Main technical features and applications of FR4 light sheet: stable electrical insulation performance, good flatness, smooth surface, no pits, standard thickness tolerance exceeding , it is suitable for high performance electronic insulation requirements, such as FPC reinforcement board, tin furnace resistance High temperature plate, carbon film, precision star wheel, PCB test frame, electrical (electrical) equipment insulation separator, insulation pad, transformer insulation, motor insulation, deflection coil terminal plate, electronic switch insulation board, etc.

Second, aluminum substrate sheet (single-sided aluminum substrate, double-sided aluminum substrate),the aluminum substrate mainly has excellent heat dissipation performance,which is suitable for LED technology, the bottom sheet is aluminum material.

The aluminum substrate is a metal-based copper clad laminate with good heat dissipation function. Generally, the single panel is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer.

It also will be designed as a double panel when used for high-end use, the structure is circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. A very small number of applications are multi-layer boards, which can be made of ordinary multi-layer boards combined with an insulating layer and an aluminum base.

The aluminum substrate is a kind of PCB. The aluminum substrate is a metal-based printed board with high thermal conductivity. It is generally used in solar energy, LED lamps and other products that require heat dissipation, but the material of the circuit board is aluminum alloy. The material is glass fiber, but because the LED heat is large, the circuit board for LED lamps is generally an aluminum substrate, which can conduct heat quickly, and the circuit board for other equipment or electrical appliances is still a fiberglass board!

Most of the LED aluminum substrates are used in led energy-saving lamps. LED TVs are also used. They are mainly used on objects that require heat conduction. Because the LED current is larger, the light is brighter, but the temperature is too high, and the temperature is too high. Outside the lamp bead, it is light decay.