Definition and classification of CCL

CCL definition—also known as substrate

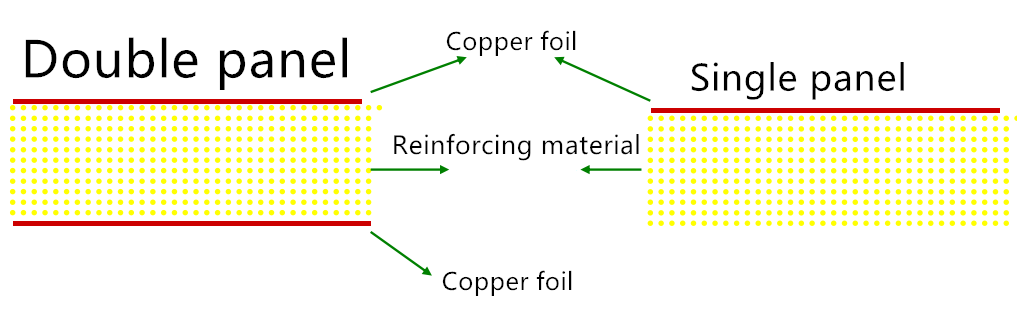

The reinforcing material is impregnated with resin, coated with copper foil on one or both sides, and a plate-like material made by hot pressing is called copper clad laminate (CCL). It is the basic material to do PCB, often called the substrate. When it is used for multi-layer board production, also known as core board (core).

For CCL type, often according to different rules, there are different categories:

Mechanical rigidity of CCL: rigid CCL (FR-4, CEM-1, etc.) and flexible CCL (FCCL, FPC, etc.).

(FR-4, CEM-3, etc.), metal-based CCL (aluminum plate, etc.), ceramic-based CCL (ceramic-based), according to different insulation materials and structure.

According to the thickness of copper cladding: divided into conventional and thin plate.

5mmConventional plate thickness ≥ 0.5mm

Thin plate thickness <0.5mm (excluding copper foil thickness)

Note: the thickness of the CCL thickness of less than 1.2mm, mostly for multi-layer board;

Thickness greater than 1.2mm, mostly for double-sided.

According to the flame retardant grade:

In accordance with UL standards (UL94, UL746E, etc.) flame retardant grades are non-flame retardant Type (HB, etc.) and flame retardant CCL (FR-4, CEM-1, FR-1, CEM-3) and so on.

According to some special performance of CCL:

Such as: high Tg plate (Tg> 170 ℃), medium Tg plate (Tg> 150 ℃), high dielectricity,High Dk, High CTI Plate, Low Thermal Expansion Coefficient Plate (Low CTE), Halogen-free plate (HF) and so on.

The composition of CCL

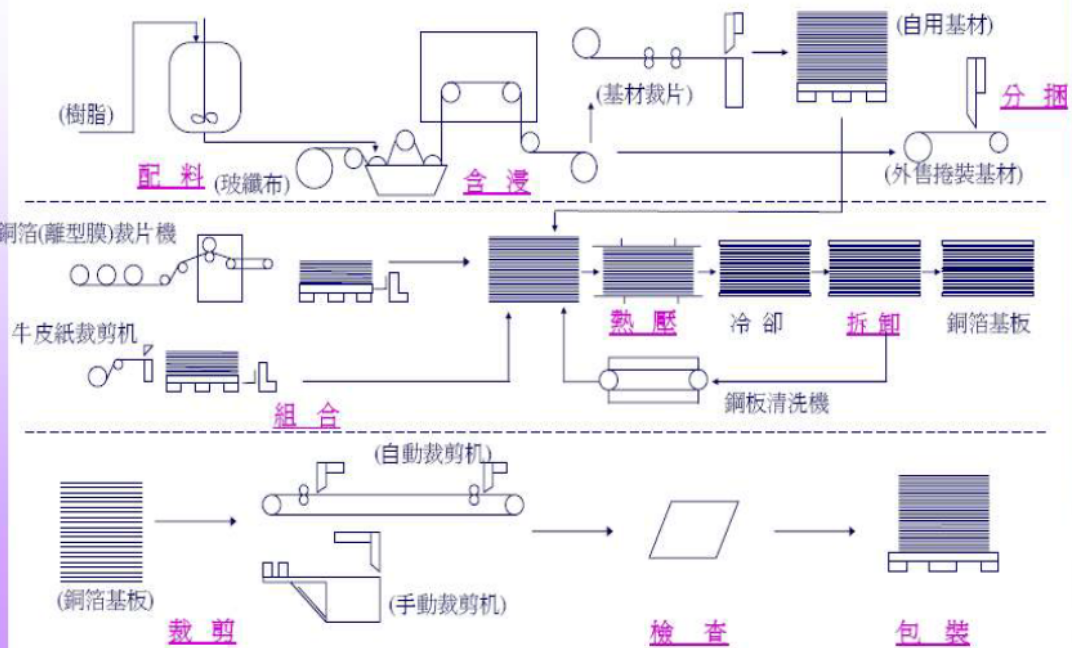

Production technology process of FR – 4 copper clad laminate

CCL performance and standard

CCL performance requirements can be summarized as the following six aspects of the requirements

Cosmetic requirements

Such as: metal foil surface pits, scratches, resin, fold, pinhole, bubbles, white wire, etc.

Size requirement

Such as: length, width, diagonal deviation, warping, etc.

Electrical performance requirements

Including the dielectric constant (Dk), dielectric loss tangent (Df), volume resistance, surface resistance, insulation resistance, arc resistance, dielectric breakdown voltage, electrical strength, compared to the tracking index (CTI), ion Migration (CAF) and so on.

Physical performance requirements

Including: dimensional stability, peel strength (PS), bending strength, heat resistance (thermal stress, Td, T260, T288, T300), punching, etc.

Chemical performance requirements

Including: flammability, weldability, chemical resistance, glass transition temperature (Tg), Z-axis thermal expansion coefficient (Z-CTE), dimensional stability and so on.

Environmental performance requirements

Include: water imbibition, pressure vessels cooking test, etc

Copper-clad laminate standard: IPC – 4101 – c

Copper-clad testing standard: IPC – TM – 650

Outlined halogen-free plate and lead-free board

Background:

July 1st, 2006 ,the EU formally implemented the RoHS directive, the global electronics industry will enter the lead-free era. The most representative lead-free solder Sn / Ag / Cu (SAC) has a melting point of 217 ° C and is about 34 ° C higher than the melting point of conventional tin-lead (SnPb) solders that have been used for a long time. Electric assembly in order to use the peak wave soldering peak temperature and reflow soldering problems have been greatly improved. These changes, for the CCL heat resistance, reliability put forward higher requirements.

RoHS directive: the core content is in the electrical and electronic equipment to limit the use of toxic substances, protect the environment, to provide green consumption, to achieve production and consumption of two areas of the eradication, harmless.

RoHS Hazardous Substances: Pb, Cd, Cd, Hg, Cr6 +, PBB, PBDE PBDE

CCL To adapt to the EU RoHS directive, CCL is adjusted from two aspects.

Halogen-free (Halogen-free): refers to chlorine (Cl), bromine (Br) content of less than 900ppm, chlorine (Cl) and bromine (Br) total content of less than 1500ppm CCL, halogen-free CCL

Flame retardant principle

Brominated resin: halogen element as a flame retardant epoxy resin, the main elements of bromine, chlorine;

Halogen-free resin: phosphorus and phosphorus-based epoxy resin, the main elements of phosphorus, nitrogen

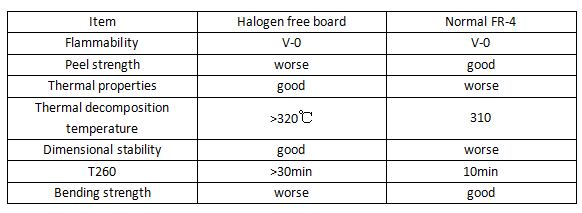

Performance comparison between halogen – free plate and ordinary CCL

B lead-free laminate :, it is copper- clad laminate in contrary to being covered with the lead-free solder on its surface;

PBB and PBDE are not used in CCL, and PBB and PBDE are not used. PBB and PBDE are not used in PBX and PBDE. For the combustion agent, the current law has not banned.

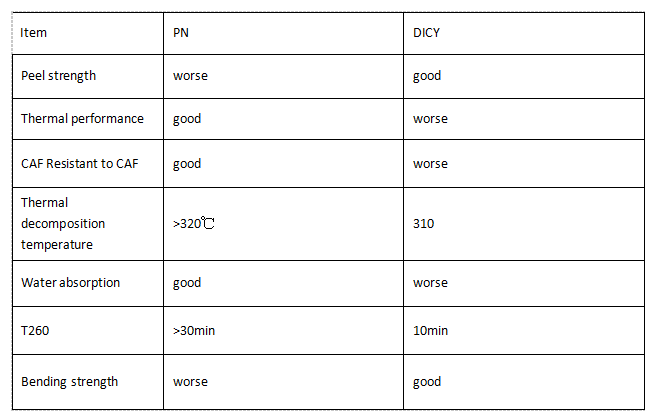

Curing system

Ordinary FR-4: dicyandiamide as curing agent curing system, DICY curing system;

Lead-free board: phenolic resin curing agent for the curing system, PN curing system

DICY and PN curing systems

Copper cladding industry to adjust the main resin and curing agent to form a copper foil and reinforcing materials, the phenomenon of poor bonding, which requires copper foil to enhance the strength of the material and enhance the anti-stripping strength (PS).

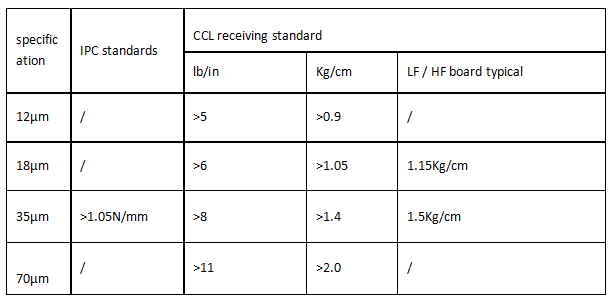

Acceptance criteria of peel resistance strength for HF and LF laminate from PCB and copper-clad laminate

misunderstanding:

High Tg plate: usually refered as high Tg plate, we believe that the anti-peeling strength of copper foil is very high.

The actual CCL industry is currently there are two high Tg plate:

Dicyanamide curing system of high Tg plate: conventional copper foil that can meet the requirements of its peel strength, such as Health benefits S1141 170, Hao Rong HRH-4170 plate; (non-lead-free board).

Phenolic resin curing system of high Tg plate: the anti-peeling strength of copper foil demanding, conventional copper foil can not meet the requirements of its anti-stripping strength, such as Health benefits S1170, tablelight EM827, Hao Rong HRH-4175 plate. (Unleaded board)

More products informations, please contact [email protected], we have a specialized technical engineers service for you, at the same time we can offer you free samples.

Copper-clad Laminate Technology Process.pdf

Copper-clad Laminate Technology Process.pdf