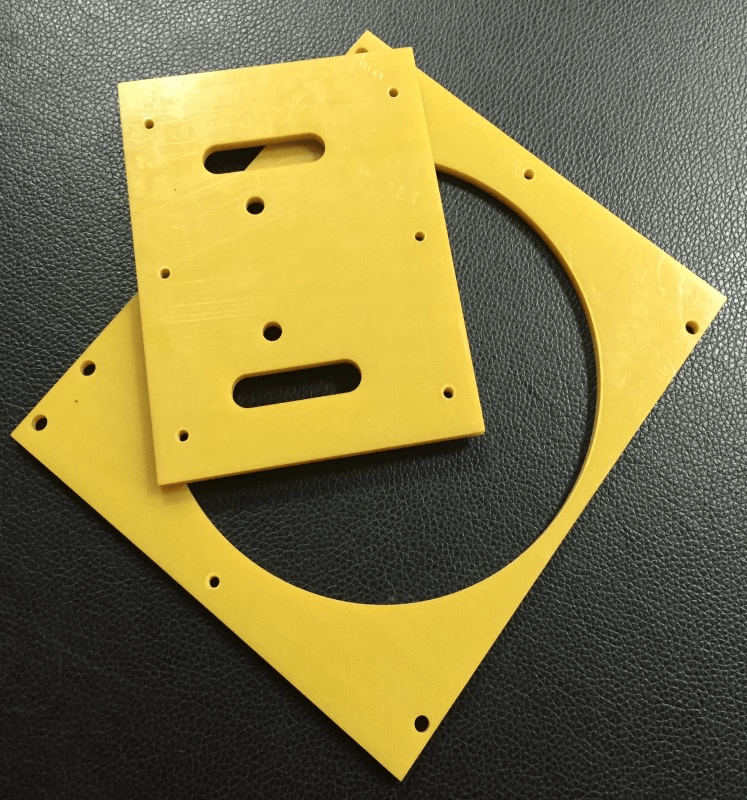

Insulation sheet is a composite material produced by the combination of glass fiber cloth and epoxy resin. This material has very good insulation performance, ultra-high hardness, excellent corrosion resistance and ultra-high flame retardancy. It is widely used in many occasions.

What fields will the insulation sheet be used in?

The common insulation sheet mainly uses its own “insulation” performance. It is widely used in some electrical equipment, conductors, and electromagnetic circuits in power systems, such as transformers. With the development of high and low level, the application of insulation sheet in high-speed rail is very extensive. In general, the insulation sheet is applied to power generation equipment, power transmission equipment, communication equipment, new energy industry, and use in the fields of electronics, electrical appliances, motors, etc.

Why are insulating materials used in these fields?

Here are two common industrial applications of power generation and transmission, insulator pollution flashover, aging and breakdown of generator and power transmission system equipment coil insulation, and transformer coil insulation breakdown at multiple voltages. These are the main causes of power system failures and power outages. Good insulation materials, during use, it can greatly avoid the above situation, maintain and ensure the stable transmission of power.

How to improve the quality of insulation sheet to meet market demand ?

With the development of the market, the power system has developed from the original low voltage to high voltage, and the transmission of electric power has developed from short distance to long distance, which has stricter quality requirements for the insulation materials used. In addition, in recent years, the development of ultra-high speed of high-speed rail, this convenient insulation material is the need for a variety of stable and safe special insulation special special insulation sheet.

In order to meet the needs of the market, the direction of the development of insulating plates mainly focuses on: high pressure resistance, impact resistance, corrosion resistance, water resistance, turbidity resistance, cryogenic resistance, radiation resistance and ultra-high flame resistance.